What are the characteristics of FPC glue dispensing machine

source:www.cnkaihui.com | Release time:2024年12月12日Correct positioning: The FPC (flexible circuit board) dispensing machine is equipped with a high-precision motion control system, which can correctly control the position of the adhesive head. It can perform correct dispensing operations in small FPC areas, with positioning accuracy typically reaching ± 0.02mm or even higher. For example, in the chip packaging process, it is necessary to correctly apply glue around the chip pins. The FPC glue dispenser can be positioned correctly to ensure that the glue is evenly distributed around each pin, avoiding glue overflow or covering other key areas, thereby ensuring a good connection between the chip and FPC.

Correct glue quantity control: This dispensing machine can correctly control the glue quantity. It can dispense glue according to preset glue parameters through precision measuring systems such as screw pumps, injection valves, etc. The precision of controlling the amount of glue can reach the level of microliters or even nanoliters. For example, in some FPC assembly processes that require strict adhesive dosage, such as in the bonding process of small electronic components, the glue dispenser can correctly distribute a very small amount of adhesive, which not only meets the bonding requirements but also does not affect the performance or appearance of the components due to excessive adhesive dosage.

2. Adapt to various adhesives and processes

Strong adhesive compatibility: FPC glue dispenser can be compatible with various types of adhesives, including epoxy resin adhesive, silicone, acrylic adhesive, etc. Different adhesives have differences in viscosity, curing characteristics, etc., and dispensing machines can adapt to these different adhesives by adjusting dispensing parameters such as pressure, speed, etc. For example, in FPC waterproof treatment that requires sealing performance, silicone glue can be used for dispensing; In the component fixing process, epoxy resin adhesive can be used, and dispensing machines can perform dispensing operations well.

Diversified dispensing process support: It supports multiple dispensing processes, such as point by point dispensing, line dispensing, filling dispensing, etc. Point by point dispensing is suitable for placing glue points at specific locations on FPC, such as at the bonding points of small components such as buttons; Linear dispensing can be used to draw adhesive lines on FPC and for making enclosures in chip packaging; Filler adhesive can be used to fill a certain area of FPC with glue, such as filling the through holes of FPC to prevent short circuits and other situations.

3. Flexible circuit board has good adaptability

Non destructive operation of FPC: The FPC dispensing machine is designed with full consideration of the characteristics of flexible circuit boards. The pressure control of its dispensing head and operating platform is very precise, which can avoid damage to the FPC. Due to the fragility of FPC, it is easy to be scratched or crushed. The dispensing machine can control the contact pressure within a safe range during the dispensing process. For example, when dispensing thin FPC, gently touching the surface of the FPC with the dispensing head can ensure the normal application of glue without causing indentation or damage to the FPC.

Adapt to FPC shape and size changes: It can adapt well to FPC of different shapes and sizes. Whether it is a small FPC used for mobile phones and other devices, or a large FPC used for industrial control equipment, the dispensing machine can complete the dispensing task by adjusting the working area and dispensing path. Moreover, for FPC with special shapes such as bending and folding, the glue dispenser can also apply glue reasonably according to their shape characteristics, ensuring that the distribution of glue on the entire FPC meets the process requirements.

4. Efficient production capacity

High speed dispensing: The FPC dispensing machine has a high dispensing speed and can complete a large number of dispensing tasks in a short period of time. The dispensing speed can be adjusted according to specific process requirements and adhesive properties. Generally speaking, hundreds of dispensing actions can be performed per minute. In the process of mass production of FPC, this high speed can significantly improve production efficiency. For example, in the FPC production line of electronic device manufacturing enterprises, glue dispensing machines quickly apply glue to a large number of FPCs, shortening the production cycle and meeting the market's demand for rapid updates and replacements of electronic products.

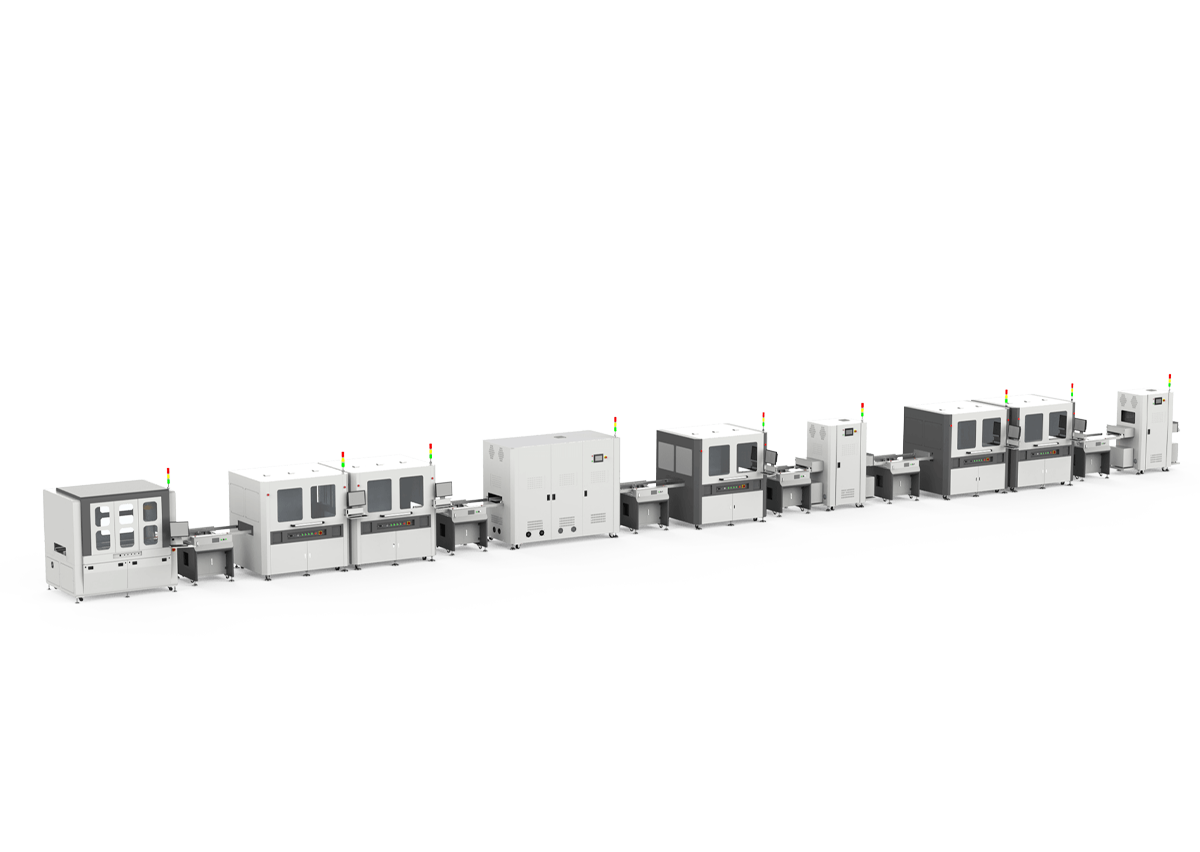

High degree of automation: It has a high degree of automation and can be linked with other production equipment such as FPC cutting machines, surface mount machines, etc. It can achieve automatic dispensing process through programming, and the entire process from FPC loading, dispensing to unloading can be automatically completed. This automated operation reduces manual intervention, improves production consistency and stability, and also reduces labor costs. For example, in automated electronic manufacturing factories, FPC dispensing machines work together with the entire production line to improve overall production efficiency and product quality.

prev:

What are the characteristics of a five axis rotar…

next:

What are the applications of servo glue line in t…

中文

中文 英文

英文

WeChat official account

WeChat official account

Scan your phone once

Scan your phone once

Wechat ID:

Wechat ID:

wechat

wechat

contact

contact

phone

phone