Where is the robot glue filling assembly line mainly used

source:www.cnkaihui.com | Release time:2024年12月25日1. Electronic and electrical industry

Consumer electronics products: Smartphones, tablets, smartwatches, and other products require sealing glue to fix, seal, or conduct heat in some internal components during production. For example, thermal conductive silicone gel is filled between the chip and the heat dissipation module. The robot glue filling assembly line can correctly control the amount and path of glue, ensuring stable heat dissipation performance and improving assembly efficiency to meet large-scale and fast-paced production needs.

Power supply equipment: various chargers, portable power banks, and industrial switch power supplies. To prevent internal components from being affected by moisture and vibration, key parts need to be glued. Robot operation can operate correctly in narrow spaces, evenly inject glue into specific positions, ensure the electrical insulation and mechanical stability of products, and extend their service life.

2. In the field of automobile manufacturing

Automotive electronic components: automotive engine control units (ECUs), onboard sensors, headlight modules, etc. These precision electronic components require high quality and consistency of adhesive filling. The robot glue filling assembly line can complete the complex glue filling process meticulously according to the preset program, avoiding situations where too much glue blocks the circuit or too little glue causes poor sealing, and improving the reliability of automotive electronic systems.

New energy vehicle battery pack: As the core of new energy vehicles, the sealing and sealing of battery modules are crucial to the safety and stability of the battery. The correct gluing of robots can not only reinforce the structure of battery modules, but also play a role in waterproofing, fireproofing, dustproof, and thermal conductivity, providing protection for the long-term stable operation of batteries.

3. Medical device industry

Small medical equipment: Household small medical devices such as blood glucose meters and blood pressure monitors, with internal circuit boards, sensors, and other components glued together, can improve moisture resistance and earthquake resistance, ensuring the accuracy of equipment measurements. The robot glue filling assembly line can meet the production standards of medical equipment, reduce human errors, and ensure product quality, safety, and reliability.

Implantable medical devices: high-value medical devices such as pacemakers and cochlear implants that are implanted into the human body, must not be compromised in terms of the injection molding process during production. Robots can perform glue filling in a sterile environment according to strict process specifications, helping products meet strict requirements such as biocompatibility and sealing, and safeguarding patient health and safety.

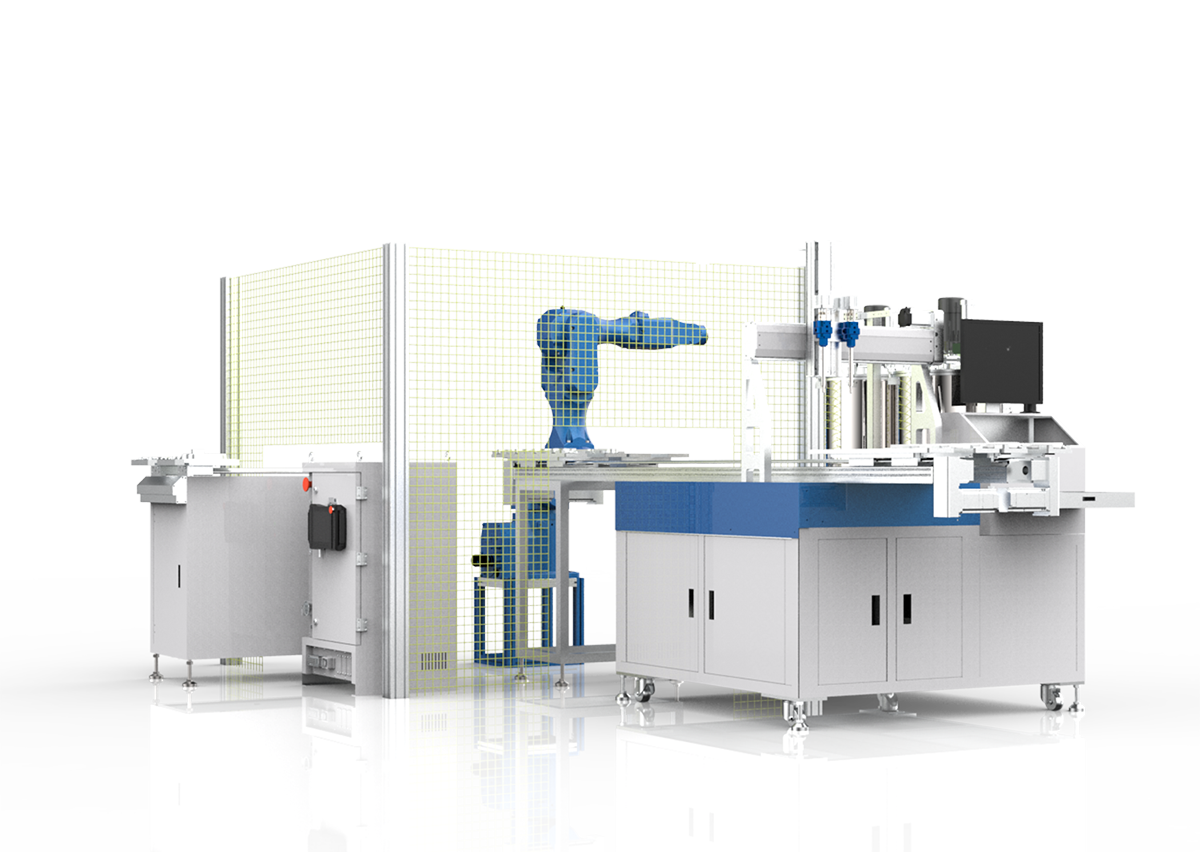

4. Self assembly of industrial automation equipment

During the manufacturing of industrial robots, automation control cabinets, and other equipment, there are also many components that need to be glued. The adoption of a robot glue filling assembly line is actually "robots serving robots", which not only accelerates the production speed of automated equipment, but also ensures the standardization of glue filling processes for equipment of the same model, strengthening the overall performance and quality of the equipment.

prev:

What are the applications of automatic glue coati…

next:

What are the characteristics of a five axis rotar…

中文

中文 英文

英文

WeChat official account

WeChat official account

Scan your phone once

Scan your phone once

Wechat ID:

Wechat ID:

wechat

wechat

contact

contact

phone

phone